Protecting business as usual for plants.

We support wide-ranging domains such as various types of equipment, tanks, piping, instrumentation/electricity, rotating machinery, and civil engineering/construction, contributing to the safe and stable operation of plants 24 hours a day, 365 days a year.

Through close communication with customers and deep understanding of work sites, we offer maintenance tailored to every plant. We meet the need for high quality and cost optimization through integrated maintenance that spans daily maintenance to turnaround work.

Serving Plants Nationwide

RAIZNEXT’s Strengths

Support available from the work planning stage Organization building and management for large-scale projects Flexible services Labor saving through technology

Abundant knowledge

Total Maintenance Service

Protecting plant value with integrated services

Daily maintenance work

RAIZNEXT maintenance personnel are stationed on the customer’s premises to handle equipment repairs and inspection work at the plant. Years of experience and systematized technology enable efficient maintenance.

We also take advantage of our on-site presence to respond quickly with emergency work. We contribute to the stable operation and quality maintenance of plants in cooperation with the customer’s maintenance department, by providing support based on our abundant maintenance experience.

Examples of Daily Maintenance Work

- Equipment overhaul, and tube bundle extraction and cleaning, due to declining heat exchanger performance

- Replacing pipes due to corrosion

- Renewing insulation materials due to declining equipment performance

- Overhaul of rotating machinery due to functional decline

- Loading arm inspection and maintenance

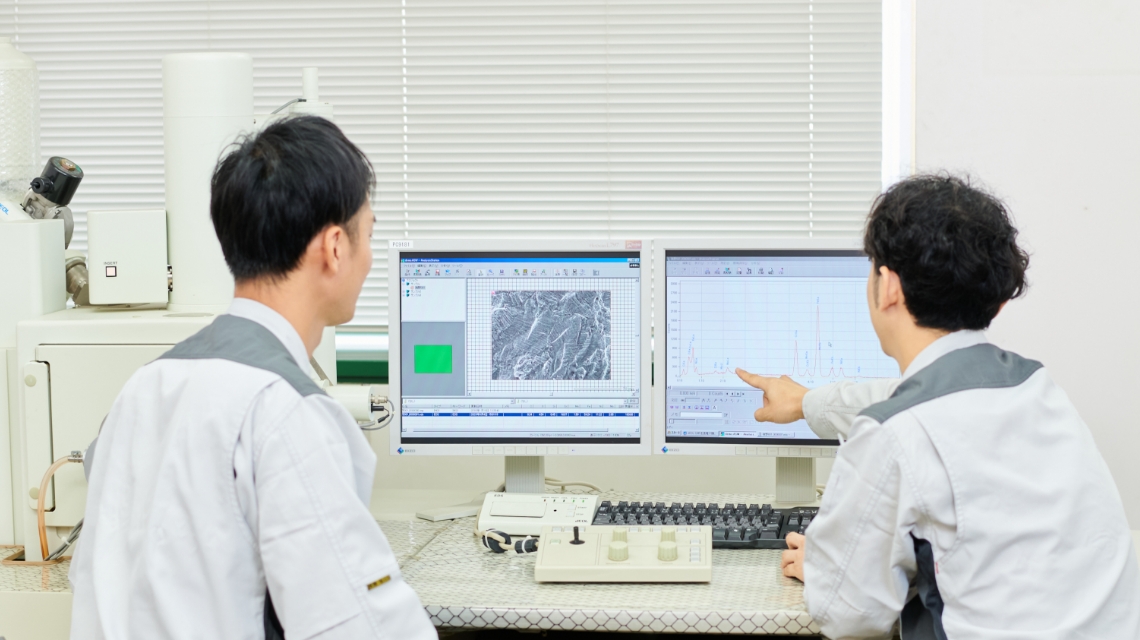

Experience-backed Support

Our record includes over 1,500 equipment diagnoses and over 600 equipment functional restorations. Databasing all these examples enables us to systematize our owned technology and adapt it to diverse cases.

Mechanization and Labor Saving in On-site Operations

We actively promote the development, introduction, and improvement of various machines, jigs, and tools in maintenance operations, including turnaround work. We maintain and improve work safety while achieving high quality, short lead times, and low costs.

Turnaround work

In close cooperation with the client, we carry out everything from basic planning to construction and inspection work. We offer construction services of high added value. As we repeatedly handle daily maintenance work and turnaround work, we become familiar with the characteristics of our customers’ plant equipment, which leads to us offering even more efficient maintenance proposals.

In recent years, we have responded to diversifying needs by providing support for detailed construction planning and facility inspection services. In addition, having construction centers located throughout Japan enables us to meet the needs of large-scale construction projects by utilizing our network of partner companies.

Turnaround work process and support content (example)

-

Contract

- Confirmation of construction requirement specifications and site inspection

- Quotation preparation, contract

-

Plan

- Designs in all categories

- Construction procedure preparation

- Procurement of materials and equipment

- Partner company arrangements

- Detailed process preparation

-

Construction

- Equipment

opening - Inspection

and repair - Restoration

- Day-by-day work plan creation

- Construction management (management of safety, quality, process, costs, etc.)

- Equipment

-

Reporting

- Report writing

- Construction evaluation meetings

- Databasing knowledge for later use in turnaround work

Rational Management of Large-Scale Projects

With more than 4,000 partner companies nationwide, we can handle large-scale turnaround work. We quickly organize in-house and partner company staff according to the scale of the project. Integrated management of safety, quality, processes, and costs through proper allocation, scheduling, and staff training.

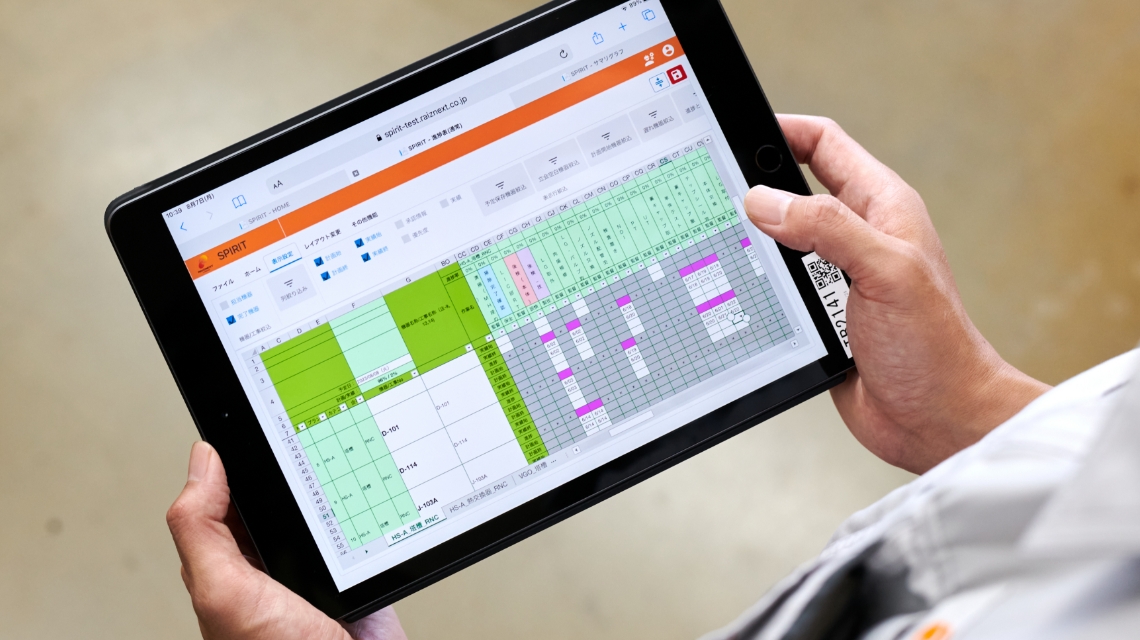

Optimizing Operations by Making Full Use of ICT

To ensure that the diverse construction processes proceed without delay, it is important to keep track of the status of the numerous staff members and various types of machinery. We deploy our self-developed information sharing and progress management system on each construction site to share progress status with our clients and move construction forward efficiently.

Supported Work Categories

Piping Work

- General piping installation and repair work

- We have a minister-certified examiners (pipes) under the High Pressure Gas Safety Act, who enables us to simplify completion inspections for high pressure gas piping work.

- Construction inspection and report compilation in accordance with various regulations and customer specifications

Static Equipment Work (towers, tanks, heat exchangers, etc.)

- General repair work

- General equipment cleaning work

- Placement and installation of new equipment, removal of existing equipment, painting, heat insulation, and other incidental work

- All overhaul inspections at the turnaround work stage

- Partial replacement of side panels, nozzles, etc. of existing equipment

Civil Engineering Work

- Pipe racks and structures - new construction

- Equipment/tank foundations - refurbishment and new installations

- Factory/warehouse construction

Instrumentation and Electrical Work

- Support for everything from on-site equipment installation to DCS works

- Specialist technicians are stationed on the customer’s premises to provide maintenance support for existing facilities

Rotating Machinery Work

- Support from installation through to maintenance

- We have established a Rotating Machinery Department to provide technical support for maintenance work nationwide, and to coordinate the mobilization of rotating machinery specialists to handle rotating machinery work at various locations.

Tank Work

- New installation work (on-site assembly work, delivery and installation of factory-made tanks)

- Modification and revamping work (modification of existing tank forms, renewal of side panels)

- Overhaul inspection, repair work, internal cleaning, and report writing