Building plants

Enhancing its value.

We provide plant engineering for a diverse range of industries, including petroleum and petrochemicals, general chemicals, nonferrous metals, and food products.

We specialize in construction of new plants as well as modification and revamping work to extend the service life of existing plants, improve seismic resistance, and increase capacity.

We provide integrated services from initial business development support to EPC, post-construction commissioning, and after-sales follow-up, acting as a good advisor helping our customers to create valuable plants that meet their needs.

Supporting a Wide Range of Industries and Business Categories

RAIZNEXT’s Strengths

Planning support from the initial stages Flexible services through our own Engineering Department Extensive knowledge of modification, revamping, and relocation

Total Engineering Services

We realize optimal plants with our integrated services, from FS/FEED to EPC.

FS/FEED(Basic Design)

As part of our business development support services, we support our clients’ investment decisions by researching and examining their needs and conditions, and studying feasibility and profitability through in-depth simulations. Once the commercialization of the project has been decided, we conduct basic design according to the plan, identify technical issues, and calculate estimated costs.

Design

We produce detailed designs based on the basic design documents.

RAIZNEXT provides design technology in the process, piping, electrical instrumentation, mechanical, and civil engineering construction fields.

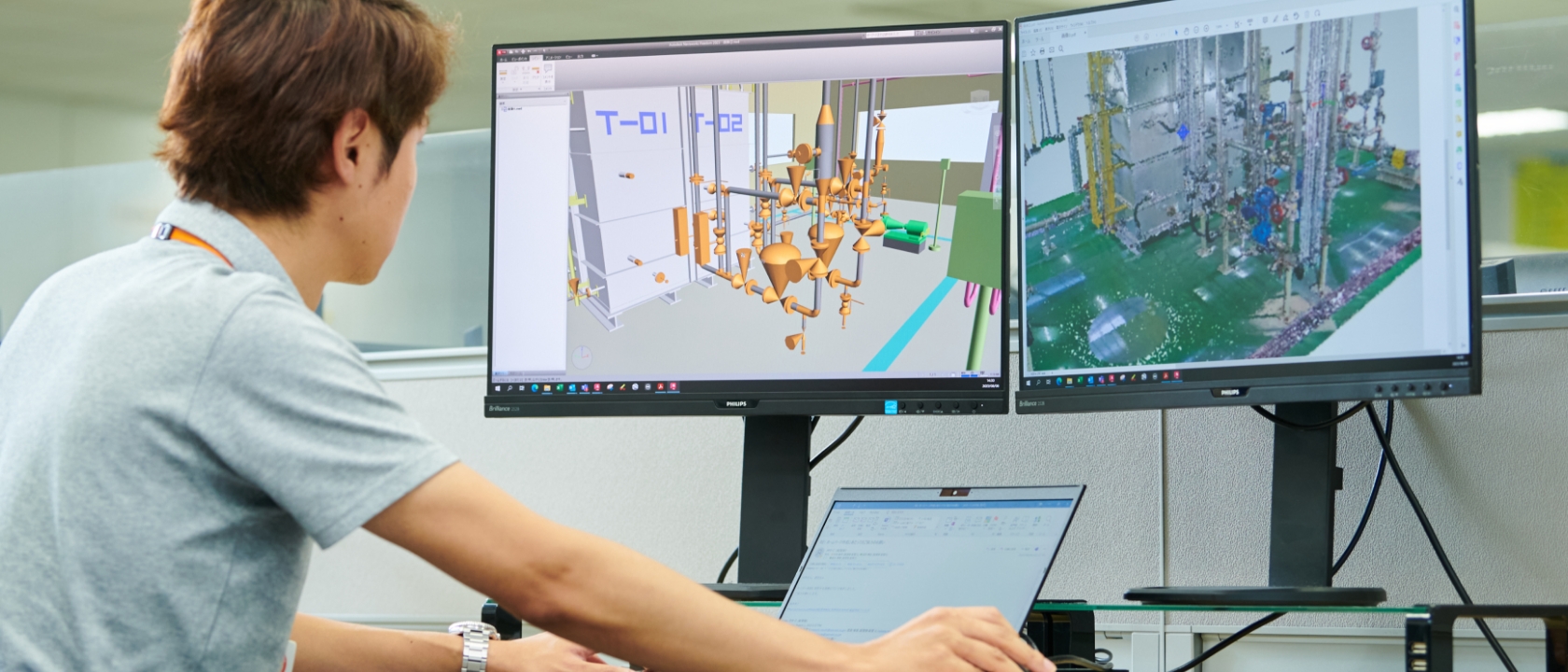

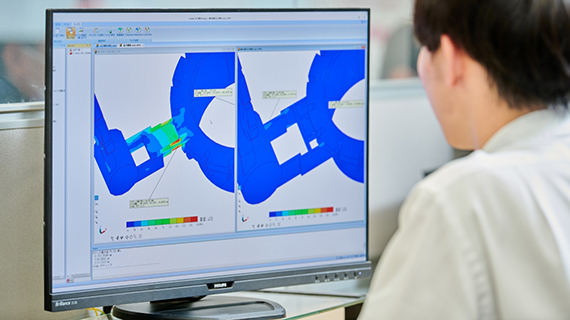

We implement rational design by actively introducing various engineering tools, such as 3D scanning to understand the current status, 3D-CAD for detailed design and verification, and CAE for structural and fluid analysis.

Procurement

From the design drawings, we calculate quantities of materials and make purchasing arrangements. We select appropriate materials in terms of quality, delivery, price, etc.

Procurement of materials

- We can order and deliver everything from piping materials to instrumentation/electrical equipment and large equipment (from general to special materials).

- Procurement functions are also set up at each business site, enabling swift order placement and delivery.

Construction Procurement

- Contracting for construction subcontracting, design subcontracting, outsourcing, and leasing

Construction

We make construction plans to appropriately reflect the design requirements. We handle all plant-related construction work, including piping, static equipment, rotating machinery, civil engineering construction, instrumentation and electrical work, and tank construction. We promote the use of various construction methods and ICT technologies, contributing to the improvement of construction safety and quality.

We can also handle the construction of existing plants that involve many technical challenges and construction restrictions, making full use of our on-site expertise and engineering techniques accumulated through our maintenance work.

New Plant Construction

We provide a full range of services from design, procurement, and on-site construction for plant building, mainly for small- and medium-scale plants in various industries.

Modification and Revamping Works

We can handle a variety of modification and revamping work, including capacity expansion, energy saving, environmental conservation, and aging countermeasures.

Commissioning

After construction is completed and before the plant and equipment are officially put into operation, commissioning ensures that there are no defects.

A series of preparatory work is performed prior to the start of commissioning, including utility acceptance, running-in rotating machines, and associated vibration measurements. Upon successful completion of the trial run, the plant is handed over to the customer.